Abstract

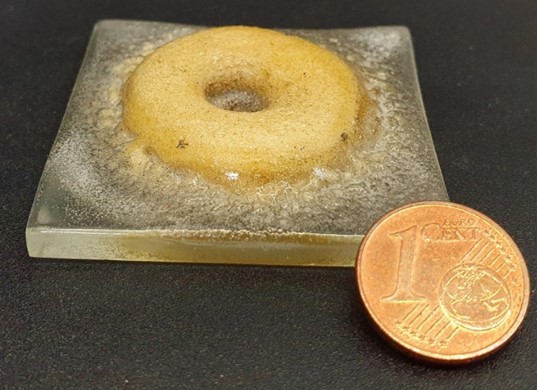

The brainwave of spray printing glass (SPG) emerged in September 2021 and has become a feasible way of applicating glass in thin layers in June 2022. The whole idea started from a sustainable motive: Can we use less material and less energy for glass elements? Based on the theoretical background of repairing old diesel engines, physical tries were made with acetylene torches blowing glass powder on a glass plate, fusing the glass powder particles to a glass panel. The first result of SPG was an opaque substrate on a transparent panel. From there on the Glass Competence Center was investigating the parameters color, transparency, interface and residual strength. Color and transparency seemed to be influenced by temperature, velocity, granulate, base material and more. This paper presents a feasibility study of spray printed glass on flat glass and shows results regarding the practical realization, pore distribution of the novel glass connections and microscopy. The current samples achieved size of 190 mm by 30 mm for soda-lime silicate glass and 200 mm by 85 mm for borosilicate glass. Larger sizes are possible and ask for investments in heat chambers, robot arms and associating torches. The dimensions of the samples can be scaled up. Spray printed glass can be used for new elements, but also to strengthen reused glass panels e.g. by making ribs. That makes spray printing glass a revolutionary product that has favorable prospects in applications in several markets.

Published

Issue

Section

Additive Manufacturing

License

Copyright (c) 2024 Matthias Seel, Erwin ten Brincke, Emanuel Nowak, Phillip Amir Chhadeh, Ulrich Knaack

This work is licensed under a Creative Commons Attribution 4.0 International License.