Mechanical Properties of Glass Plate During Anticlastic Cold Bending

DOI:

https://doi.org/10.47982/cgc.9.613Downloads

Abstract

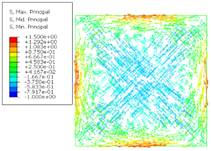

Anticlastic glass surfaces play a significant role in free-form glass facades. For realizing anticlastic surface, cold bending by loading at the corner of the plate is more adaptive and more economic than traditional hot bending method. Previous research on anticlastic cold bending mainly focuses on the description of instability phenomenon and qualitative analysis of parameters. However, the failure mechanisms of glass plates during cold bending and the influence of lamination remains unclear. In this paper, the anticlastic cold bending test was conducted to explore the influence of various factors, including aspect ratio, scale and composition of the plates. Subsequently, an effective finite element model was established and validated by test results, which is used for further explore the cold bending controlling condition for better engineering practice. The failure modes are considered as instability and strength failure. For laminated glass, maximum stresses can be derived from monolithic glass based on equivalent thickness method. The instability is induced by the compression area in the middle surface of glass plate which is significantly influenced by the composition of the laminates. Consequently, thin glass laminates exhibit enhanced stability because a reduced glass to PVB thickness ratio changes the compression area from bi-directional to uni-directional.

Published

Issue

Section

Curved Glass

License

Copyright (c) 2024 Xiaohan Hao, Suwen Chen

This work is licensed under a Creative Commons Attribution 4.0 International License.