In-Process Breakage Analysis of Tempered Glass Based on Fluid-Structure Interaction Approach

Abstract

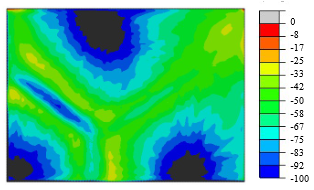

In recent decades, there has been a perceptible transformation in how glass is perceived, evolving from being used for its aesthetic appeal to being acknowledged for its structural capabilities. Structural glass components are most often heat treated to increase their ultimate strength. For this purpose, the tempering process is applied. In this context, air is the quintessential cooling technique employed to rapidly cool and fortify the material due to its associated low cost. Nevertheless, it may encounter certain limitations when quenching low thickness components, making other techniques, such as spray mist cooling, to gain traction. Additionally, glass is a very brittle and sensitive material to local stress concentrations. Thus, depending on how the tempering process is performed, an excessive and/or non-homogeneous cooling might result in local residual stresses, which may exceed the allowable strength and cause premature fracture of the material. To this end, a fluid-structure interaction approach is proposed to consider the local phenomena during the glass cooling process. The defined nozzle configuration is observed to play a significant role on the residual stress distribution of heat treated components. In addition, water mist cooling is able to temper thin glass but, at the same time, large tensile residual stresses might develop during the cooling down process. The obtained numerical results are in good agreement with previous experimental investigations available in the literature.

Published

Issue

Section

Experimental & Numerical Investigations

License

Copyright (c) 2024 Asier Iglesias, Manex Martinez-Agirre, Iñigo Llavori, Jon Ander Esnaola

This work is licensed under a Creative Commons Attribution 4.0 International License.