New Generation of Bending Tempering Equipment

Sustainable Configurations for Double Curved and Spherical Glass

DOI:

https://doi.org/10.47982/cgc.9.560Downloads

Abstract

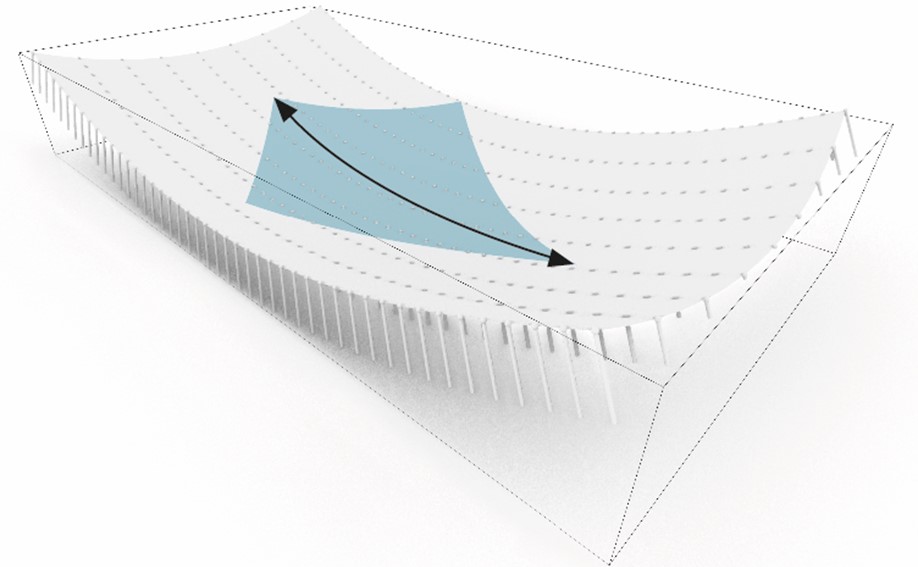

This paper reveals the new manufacturing possibilities for spherical and some organic geometries, taking advantage of state-of-the-art equipment for tempering and heat strengthening. Free forms in architecture have become increasingly prevalent with the advancement of computer-aided design. Glass is an essential building material and we have seen it used in outstanding structures, façades, skylights and other applications. On some occasions, desired geometries have been achieved by projecting flat triangular complex layouts while in other cases, the design team may have pushed for curved glass with smooth surfaces. In the realm of flat glass, tempering has been the most efficient practice to increase the glass strength. However, when it comes to doubly curved glazing, the options are limited to slumped laminated configurations due to known constraints in load-bearing capacity. While architects continue to explore challenging geometries, and engineers search for technical solutions to meet the demands of each new project, the industry has come up with the daring project-based solutions to meet the most demanding requirements. New developments in the construction industry, such as The Henderson tower by Henderson Land in Hong Kong and the L'Oréal's Innovation Centre in Paris, are pushing the boundaries and verifying the new manufacturing possibilities. Double curved and spherical tempered glass design measuring up to 6.5 m x 3.6 m is now a reality.

Published

Issue

Section

Curved Glass

License

Copyright (c) 2024 Joan Tarrús, Julian Hänig

This work is licensed under a Creative Commons Attribution 4.0 International License.