Adhesion of Laminated Glass Interlayer in a Double Cantilever Beam Test

DOI:

https://doi.org/10.47982/cgc.9.543Downloads

Abstract

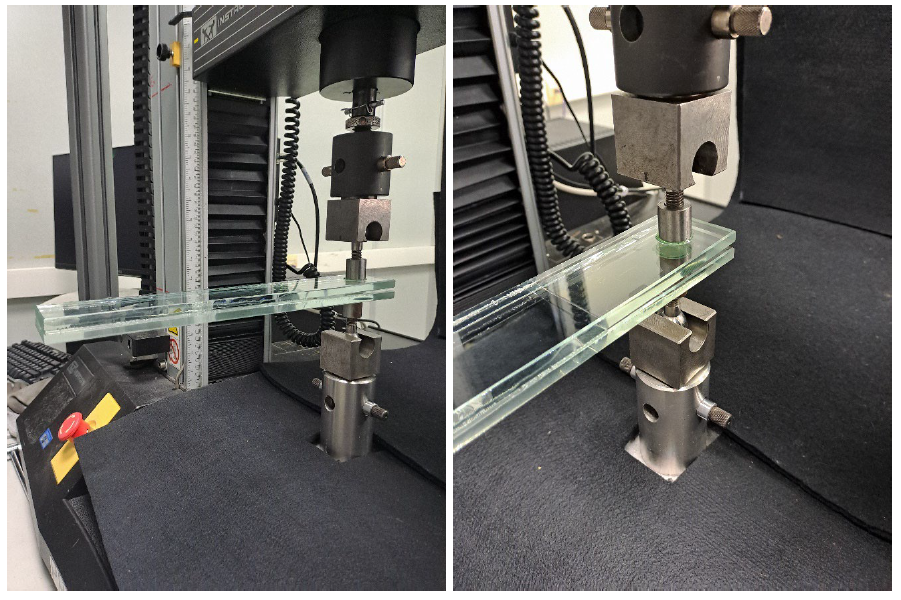

Laminated glass is a key safety element in modern building with glass façades. Tuning the adhesion between the interlayer and the glass as well as the mechanical properties of the interlayer are essentials to both the quality of the laminated glass manufacturing and to the final performance, especially regarding their wind-load and impact resistance. Adhesion tests conducted on laminated glass include pure shear and tensile loading tests. However, certain assembly geometry and framing systems lead to more complex loadings being applied on the laminated glass. We focus in this study on the Double Cantilever Beam (DCB) test that models one of these configurations. We compared three different types of typical interlayers used in the building industry, a standard Poly Vinyl Butyral (PVB), a structural PVB and an ionomer interlayer. We conducted tests at different temperatures and loading speeds to screen a broad range of conditions seen by the interlayer in the field. We found that the nature of the interlayer has a dramatic impact on the measured adhesion to glass which is directly linked to its mechanical properties and to the experimental conditions. In the specific loading conditions of the DCB test, we have identified for each interlayer, a regime of low adhesion levels combined to a rapid propagation of the delamination front under certain temperatures and loading speeds.

Published

Issue

Section

Laminated Glass & Interlayer Properties

License

Copyright (c) 2024 Paul Elziere, Yael Bronstein, Fabien Levasseur, Francis Serruys

This work is licensed under a Creative Commons Attribution 4.0 International License.