Design of Additive Manufactured Glass Components for Glass Point Fixings

Abstract

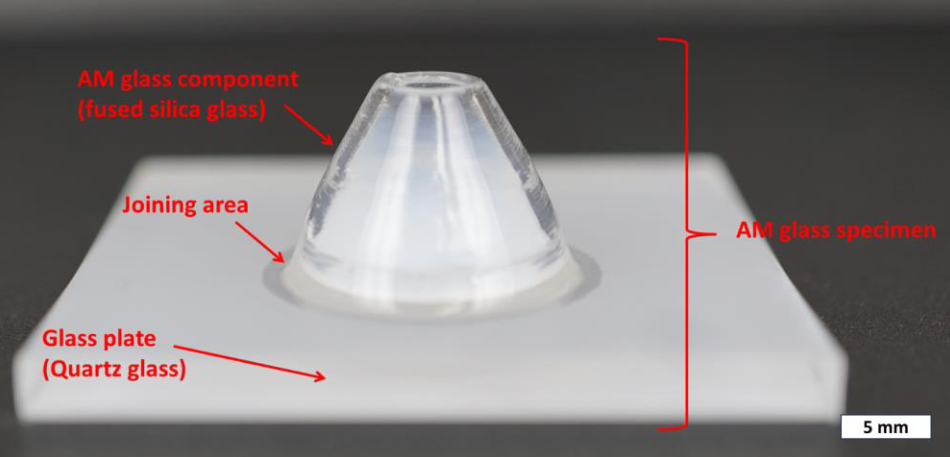

Additive manufacturing (AM) has opened new possibilities in many disciplines. Complex geometries can now be created from a variety of materials and material compositions that were previously unimaginable. As a result, there is also the potential for customization and personalization for each user. The present paper and the related research provide insight into the possibilities to further process glass by additive manufacturing methods and thereby exploring the potential for the built environment. This research focuses on developing AM glass components to be used as point fixings for flat glass elements. The innovative laser glass deposition printing process (LGD), developed by Laser Zentrum Hannover e.V., involves locally heating fused silica glass fibres with a CO2-laser, enabling precise deposition of viscose glass on substrates of the same material. In order to implement the LGD process in glass facades an examination of the component is required. This paper introduces a series of mechanical examination techniques, such as indentation and bending tests. The results derived from the testing are the foundation for a parameter study in order to develop a button shaped point fixing for glass facades.

Published

Issue

Section

Additive Manufacturing

License

Copyright (c) 2024 Philipp Amir Chhadeh, Khodor Sleiman, Henriette Hoffmann, Nicole Funke, Katharina Rettschlag, Peter Jäschke, Mascha Baitinger, Ulrich Knaack, Stefan Kaierle, Matthias Martin Seel

This work is licensed under a Creative Commons Attribution 4.0 International License.