Reuse and Remanufacturing of Insulated Glass Units

Abstract

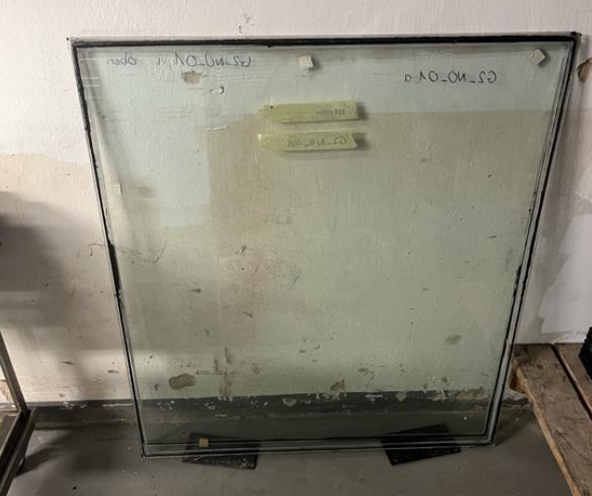

Many office and residential buildings in Europe need to be renovated in the near future to meet current energy efficiency requirements. This often comes down to updating the insulation performance of the building envelope including the windows. Most “old” windows consist of a frame and a double insulated glass unit (IGU) or even monolithic glass panes – typically without any low-e coating. These non-coated double glazings have an Ug-value of 2.7 W/m²K (single glazing even 5.2 W/m²K). Modern coated triple glazed IGUs provide Ug-values of up to 0.5 W/m²K. This paper deals with the question of how old insulating glass units can be re-manufactured to match the state of the art in terms of the energy efficiency. For this purpose, dismounted IGUs from the 1980s are used. After analyzing the remaining functionality, the double IGUs are disassembled. The single glass pane is cleaned, and the old edge sealing is removed. The old glass pane is combined it with a new coated low-e glass and a spacer system to form a new upgraded IGU with warm edge technology. This study demonstrates that remanufactured IGUs can achieve the performance of IGUs made from new glass.

Published

Issue

Section

Circularity & Sustainable Solutions

License

Copyright (c) 2024 Martien Teich, Christian Scherer, Miriam Schuster, Max Brandenstein, Michael Elstner

This work is licensed under a Creative Commons Attribution 4.0 International License.