Ten Years of Stiff PVB: An Overview of Developments and Current Status

DOI:

https://doi.org/10.47982/cgc.9.508Downloads

Abstract

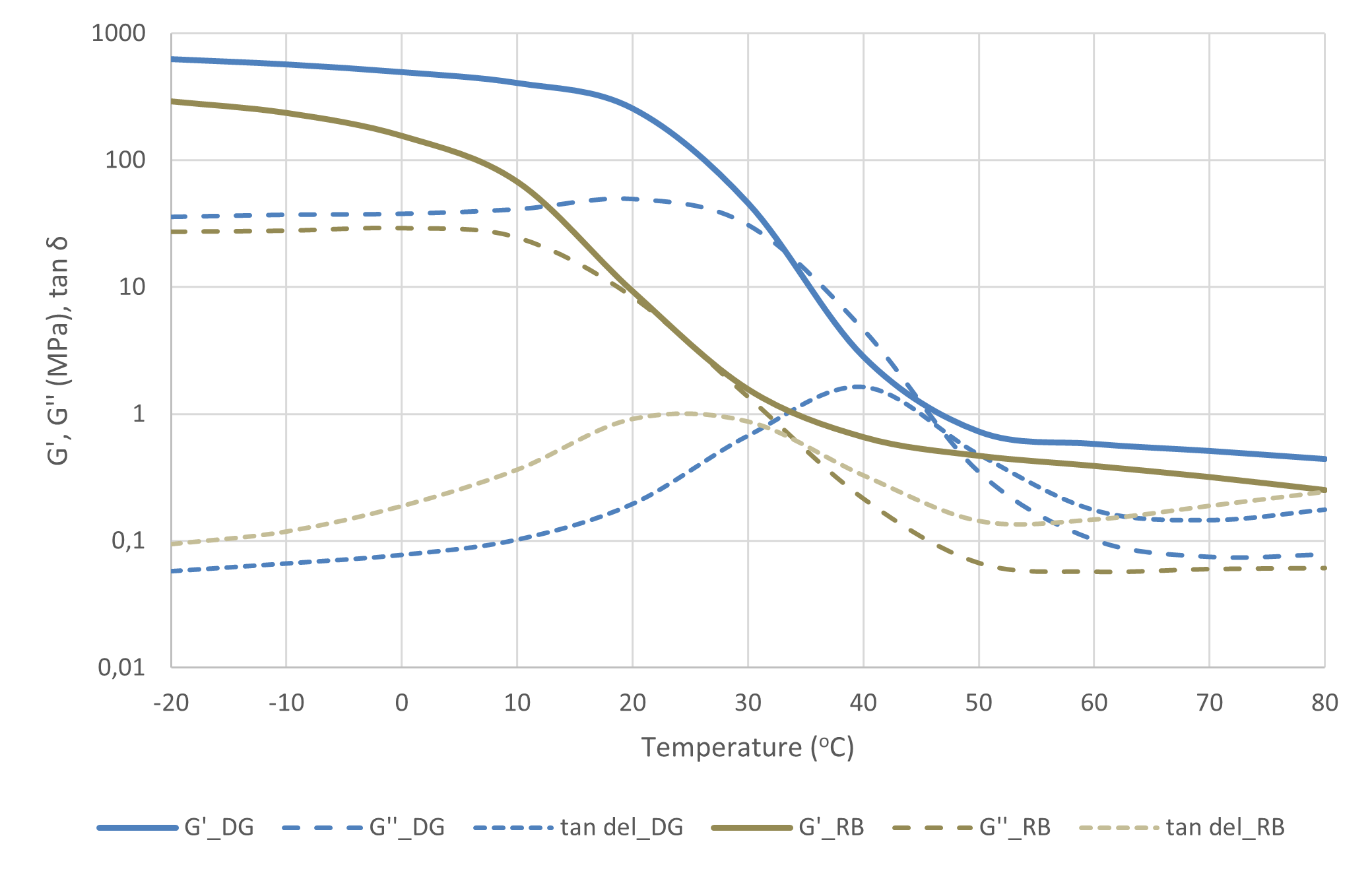

Around ten years ago, reduced plasticizer content poly(vinyl butyral) (PVB) interlayer types were introduced to the laminated glass market for use in general construction. The main purpose of these interlayers is to reduce the glass thickness or enable larger glazing spans. In these stiff PVB types, the plasticizer level is reduced to around 17 weight %, as compared to around 27 weight % for conventional PVB types. Although it was known at the time that these formulations can meet safety requirements for laminated glass, the options for use in structural design of laminated glass were less apparent. This was due to a lack of suitable standards and/or national approvals on one hand, and a lack of broader set of performance data on the other hand. Meanwhile, many of these gaps have been addressed, and performance data from various suppliers have been on a converging path, as progress in standardization was made and best-practices emerged. In addition, interest in the use of stiff interlayers in general has recently intensified, as they can improve carbon footprint of laminated glass and facades. This article aims to cover these developments, as well as providing complimentary information on some aspects. Eventually, stiff PVB’s have become a viable interlayer choice in suitable laminated glass applications, supported by a substantial amount of performance data from multiple suppliers. Drivers for the use of this material category have changed from merely economic to supporting sustainability targets through carbon footprint reduction.

Published

Issue

Section

Laminated Glass & Interlayer Properties

License

Copyright (c) 2024 Wim Stevels

This work is licensed under a Creative Commons Attribution 4.0 International License.