Experimental Characterisation and Calibration of Hyperelastic Material Models for Finite Element Modelling of Timber-Glass Adhesive Connections under Shear and Tensile Loading

Abstract

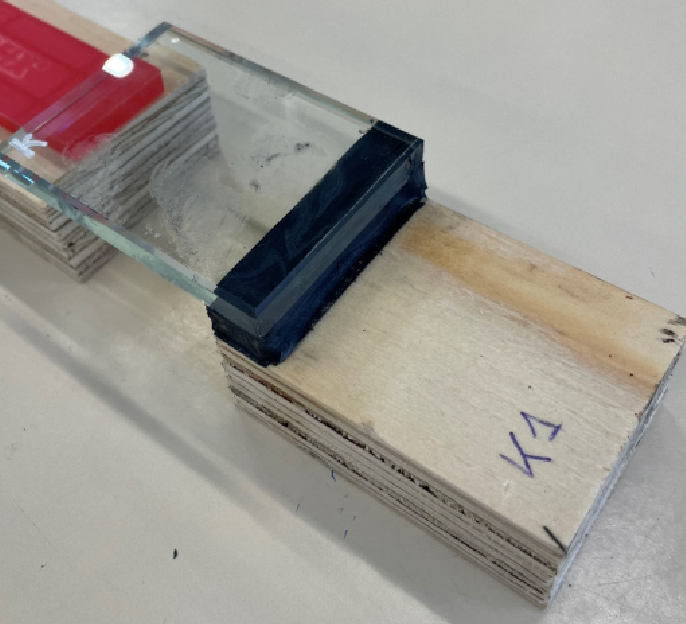

This work aims to characterise the behaviour of structural adhesives for timber-glass connections by performing experimental tests and calibrating numerical models. An adhesive bond between timber and glass can solve two conflicting requirements in timber frame structures.: i) horizontal stability provided by shear walls/vertical diaphragms; ii) large open spaces to maximize the flexibility of the building's use. One solution to this challenge is to increase the number of diaphragms in the timber frame building's façade, which can be achieved by structurally activating the glass panels. This, in turn, requires a strong structural bond between the timber and glass. Therefore, in this paper, experimental tensile and shear tests are performed on bonded timber-glass specimens with five different structural adhesives. Special attention is put on the failure behaviour of the adhesives, where both cohesive failure and loss of adhesion were identified. The nonlinear stress-strain behaviour of these adhesives is evaluated and used to asses different hyperelastic material models. Two calibration methods are used to determine the model parameters of the hyperelastic material models. Simulations have shown that the first method, assuming uniaxial tension, was not suitable for the performed tensile tests. However, with the second method, using an inverse parameter fitting method, a better approximation was obtained. The results from this work can be used to model bonded timber-glass connections in larger structures more accurately. The nonlinear stress-strain behaviour of the adhesives can be represented with hyperelastic material models. The experimental data is compared to existing hyperelastic material models where available. In case existing models are lacking, the experimental data is used to determine the model parameters. Finally, suitable stress and strain failure criteria are determined. The results from this work can be used to model bonded timber-glass connections in larger structures more accurately.

Published

Issue

Section

Adhesives & Composites

License

Copyright (c) 2024 Tine Engelen, José Henriques, Bram Vandoren

This work is licensed under a Creative Commons Attribution 4.0 International License.