Influence of a Multilayer Interlayer with a Stiff Core on the Performance of Laminated Glass

Abstract

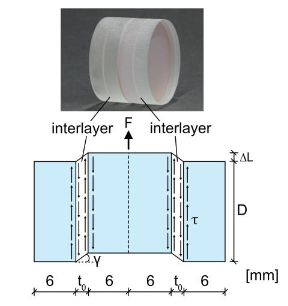

Laminated safety glass is an important component of modern façade structures and is used when higher safety requirements are demanded. The interlayer increases the stiffness due to the available shear action, ensures the residual load-bearing capacity of the structure in the event of failure and holds broken pieces of glass in place. However, the stiffness and tensile strength of conventional interlayers such as EVA or PVB are known to strongly depend on time and temperature. This phenomenon is particularly critical for the behavior of glass panes during impact and after breakage when high tensile stresses occur in the interlayer. A film with higher stiffness, lower time and temperature dependence can be laminated between two layers of interlayer material to improve laminated glass behavior. Given the need to conserve resources and reduce weight, the question arises as to whether such an interlayer could also be used to meet the safety requirements for laminated glass made out of thin glass. In this study, the influence of a multilayer interlayer of EVA and a stiff core film of modified polyester (MPE) in glass laminates was examined. For this purpose, the material and composite behaviors were experimentally studied and evaluated. This article presents the test setup and the results. The focus is on comparing the properties of interlayers with and without MPE films. The results show that the impact strength of thin glass laminates is improved by the multilayer interlayer.

Published

Issue

Section

Laminated Glass & Interlayer Properties

License

Copyright (c) 2024 Elena Fleckenstein, Steffen Bornemann, Abdus Salam, Jasmin Weiß, Michael Engelmann

This work is licensed under a Creative Commons Attribution 4.0 International License.