Structural Topology Optimization for Abrasive Water-Jet Fabricated Glass

DOI:

https://doi.org/10.47982/cgc.9.485Downloads

Abstract

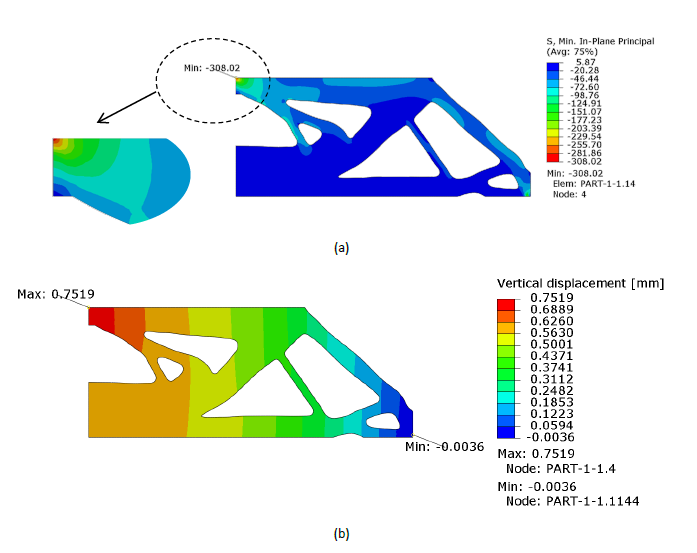

The application of structural topology optimization to glass may enable the design of architectural and lightweight glass structures. There is still a lack of specific topology optimization tools for such a brittle material. This work establishes a topology optimization computational method for the design of glass structures fabricated via abrasive water-jet cutting. This allows to obtain load-bearing glass components which can have a high strength-to-weight ratio while accounting for changes in mechanical properties induced by the fabrication process. Here, we consider a volume minimization problem in which global displacement and global maximum principal stress design criteria are considered. The optimization algorithm is developed based on a density method with a robust filtering method. The Method of Moving Asymptote (MMA) is used as the standard optimizer. The numerical examples are presented in both 2D and 3D design structures. We perform topology optimization with mechanical properties specifically obtained experimentally for water-jet cut glass. We find that customized topology optimization can minimize effectively the volume of the structures and improve structural performance.

Published

Issue

Section

Experimental & Numerical Investigations

License

Copyright (c) 2024 Kimhong Heng, Maxime Vassaux, Raveth Hin, Chansopheak Seang, Eric Robin, Jean-Christophe Sangleboeuf

This work is licensed under a Creative Commons Attribution 4.0 International License.