Methods for Dimensioning an Adhesive Joint for Use in Fluid-Filled Façade Element

DOI:

https://doi.org/10.47982/cgc.9.475Downloads

Abstract

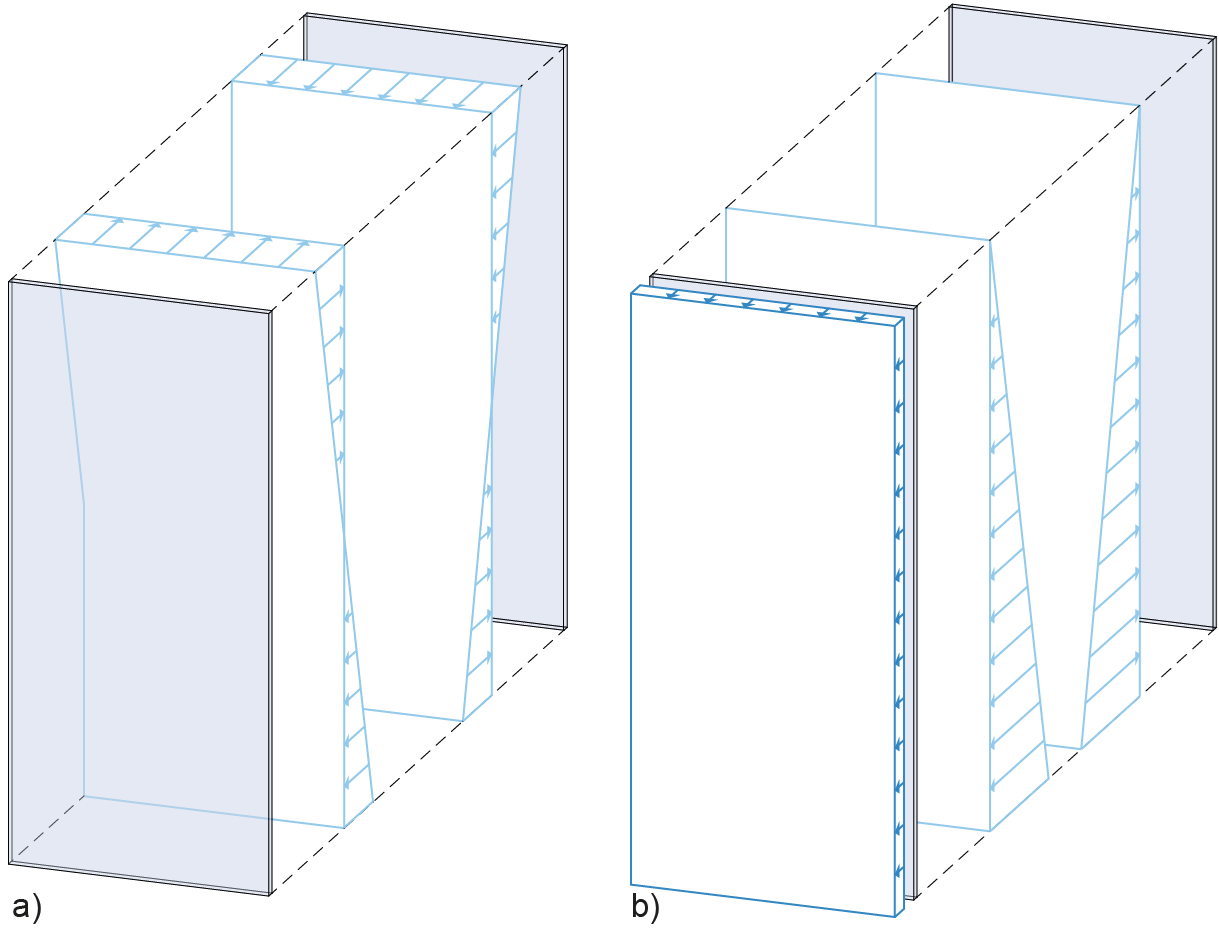

Fluids in the cavity can be used to integrate additional functions into insulating glazing. However, the high permanent load exerted by the fluid on the glazing and surrounding components is problematic. Conventional design methods result in large adhesive joints, which are not desirable from an aesthetic point of view. ETAG 002-1 is typically used for the design of structural adhesive bonds for use in structural glazing façades. However, the calculation is considered to be conservative. In particular, it is criticised for its deterministic safety concept. Therefore, in recent years, a number of researchers have looked at different methods for the design of adhesive joints. Such methods are presented by the Fachverband Konstruktiver Glasbau e.V. in the Technical Note FKG 01/2021. A further approach is presented by Drass & Kraus (2020, 2021a, 2021b), who proposes an approximation to the semi-probabilistic safety concept and thus to the current Eurocode 0 design standard by determining a material safety factor. This paper is concerned with the design of a load-bearing adhesive joint for use in a fluid-filled insulating glass unit. A specific façade element is used as an example for the calculations. Three dimensioning methods are compared: the analytical method according to ETAG 002-1, a numerical method according to Technical Note FKG 01/2021 and the approximation of a semi-probabilistic safety concept according to Drass & Kraus (2020, 2021a, 2021b). The results show significant differences between the design methods in terms of utilisation.

Published

Issue

Section

Adhesives & Composites

License

Copyright (c) 2024 Alina Katzera, Michael Engelmann, Bernhard Weller

This work is licensed under a Creative Commons Attribution 4.0 International License.