Silicone Structural Glazing Under Blast Loading

Abstract

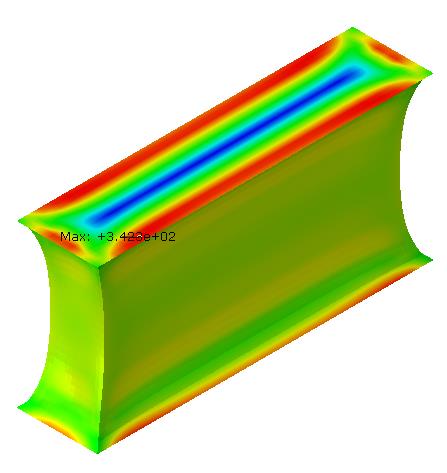

Silicone sealants have a long history of successful use in high performance windows and curtainwalls, such as structural glazing (bonding) systems which can contribute to bomb blast mitigating window designs. Previous experimental work illustrated the increase in strength and elongation for silicone sealants at the typically higher strain rates of blast loading. These values have been used as design values for joint dimensioning. With the advent of more sophisticated analysis methods using finite element analysis software and the desire to optimize geometries of structural joints in high performance designs with extreme blast loads, there is a need to provide better material behavior models for silicones able to reproduce the typical loading during blast events. In a first step, small scale testing of various joint configurations at increased speeds was used to determine suitable material models. Next, the material model was validated using experimental test results of blast loaded adhesively bonded assemblies. Based on the obtained results, criteria for failure prediction are identified and suitable design strength values as well as joint dimensioning guidelines for engineering bonded systems are provided.

Published

Issue

Section

Joints, Fixings & Adhesives

License

Copyright (c) 2022 Valérie Hayez, Jon Kimberlain, Jie Feng, Sigurd Sitte, Mark Mirgon

This work is licensed under a Creative Commons Attribution 4.0 International License.