Evaluation Methods for Surface Compression Stress Measurements with Unknown Principle Stress Directions

Abstract

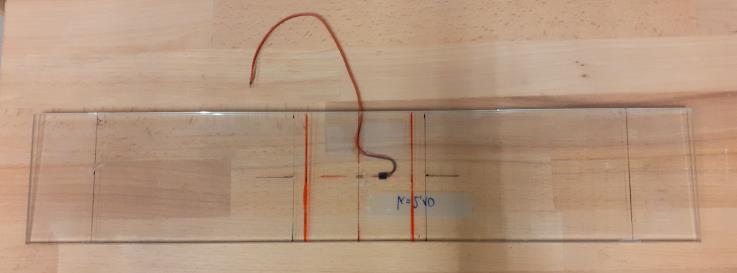

The birefringent properties of glass can be well utilized for non-destructive testing of thermally tempered glass. The surface compression stress as well as the compression zone depth of thermally tempered glass is commonly measured with a scattered light polariscope. The measurement with scattered light polariscope provides information about stresses acting perpendicular to the measurement direction. Therefore, the measurement depends on the direction. In order to make a statement about the rough level of the prestress, a measurement in one direction can be sufficient, assuming an isotropic stress state and a relatively homogeneous distribution of the surface compression stress. However, in order to be able to make a more detailed statement about a non-isotropic stress state, measurements in up to four directions are necessary. Information about the direction of principal stresses and differences of principal stresses can then be evaluated. In the present work, it is investigated which deviations can be expected by measurements performed in only one direction or by measurements using up to four directions. For this purpose, five methods are introduced, which deviate in the assumptions made for the current stress state. The methods are compared using measurements on thermally tempered glass in a four-point bending test and on thermally tempered glass specimens without any external load.

Published

Issue

Section

Numerical Modeling & Experimental Validation

License

Copyright (c) 2022 Kerstin Thiele, Steffen Müller-Braun, Jens Schneider

This work is licensed under a Creative Commons Attribution 4.0 International License.