Thermal Rheological Behavior of Composite Interlayer in Laminated Glass

DOI:

https://doi.org/10.47982/cgc.8.408Downloads

Abstract

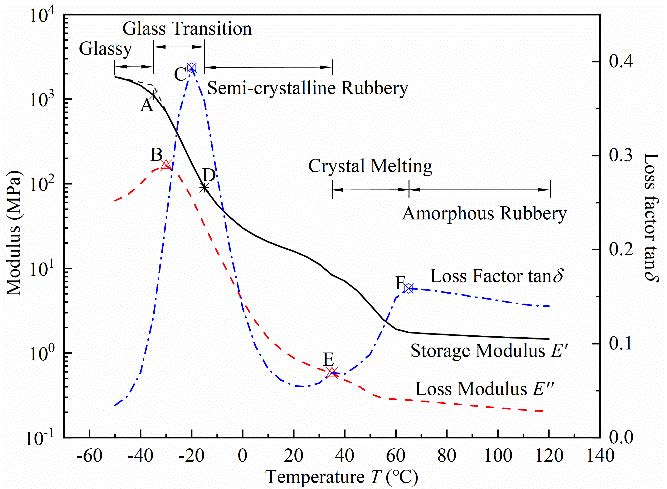

Laminated glass is growing its application in structural entities. The thermoplastic polymeric interlayer plays an important role in transferring force and achieving the composite action in laminated glass, which reveals evident temperature-dependent behavior. In this study, a novel composite interlayer (SGE®) was devised to improve the resistance of laminated glass against environmental actions and to enhance the post-fracture performance. It is comprised of modified ethylene-vinyl-acetate (PVE®) and polycarbonate (PC). Through dynamic mechanical thermal analysis, the temperature-dependent characteristics of SGE, PVE, and PC materials were investigated in detail. The results show that the thermal rheological behavior of SGE is similar to that of PVE. The temperature ranges of glass transition and crystal melting of SGE material are -35°C ~ -25°C and 45°C ~ 75°C, respectively. The corresponding ranges are -35°C ~ -15°C and 35°C ~ 65°C for PVE material. And temperature ranges of the main transition are influenced by imposed frequency. Besides, the relationship between time and temperature for PVE, PC, and SGE material is extensively complicated and the complexity depends on the investigated mechanical property, temperature range, and time range. And the simple thermal rheological behavior emerges in the storage modulus of polymers, but loss modulus and loss factor conform to the complex thermal rheological behavior at the temperature range of -50°C ~ 120°C under the frequency range of 0.1 Hz ~ 10 Hz.

Published

Issue

Section

Laminated Glass & Interlayer Properties

License

Copyright (c) 2022 Dongdong Xie, Jian Yang, Xinger Wang, Chenjun Zhao, Xianfang Jiang, Gang Li

This work is licensed under a Creative Commons Attribution 4.0 International License.