Experimental Investigation of a Transparent Interface Material for Glass Compression Members

DOI:

https://doi.org/10.47982/cgc.8.395Downloads

Abstract

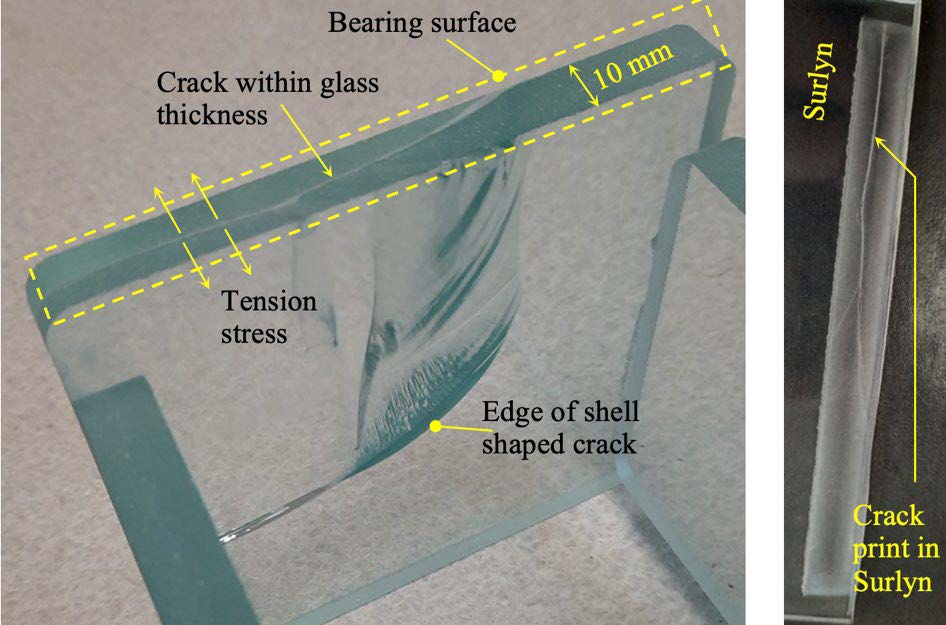

In this experimental research a transparent thermoplastic manufactured by the DOW Corporation and known as Surlyn is investigated for use as an interface material in fabrication of an all-glass pedestrian bridge. The bridge is modular in construction and fabricated from a series of interlocking hollow glass units (HGU) that are geometrically arranged to form a compression dominant structural system. Surlyn is used as a friction-based interface between neighbouring HGUs preventing direct glass-to-glass contact. An experimental program consisting of axial loading of short glass columns (SGC) sandwiched between Surlyn sheets is used to quantify the bearing capacity at which glass fracture occurs at the glass-Surlyn interface location. Applied load cases include 100,000 cycles of cyclic load followed by 12 hours of sustained load followed by monotonic load to cracking, and monotonic loading to cracking with no previous load history. Test results show that Surlyn functions as an effective interface material with glass fracture occurring at bearing stress levels in excess of the column-action capacity of an individual HGU. Furthermore, load cycling and creep loading had no effect on the glass fracture capacity. However, the load history had a nominal effect on Surlyn, increasing stiffness and reducing deformation.

Published

Issue

Section

Numerical Modeling & Experimental Validation

License

Copyright (c) 2022 Joseph Robert Yost, Matthew Cregan, Mohammad Bolhassani , Masoud Akbarzadeh , Yao Lu , Philipp Amir Chhadeh , Jens Schneider

This work is licensed under a Creative Commons Attribution 4.0 International License.