Application of an Iron-Based Shape Memory Alloy for Post-Tensioning Glass Elements

Abstract

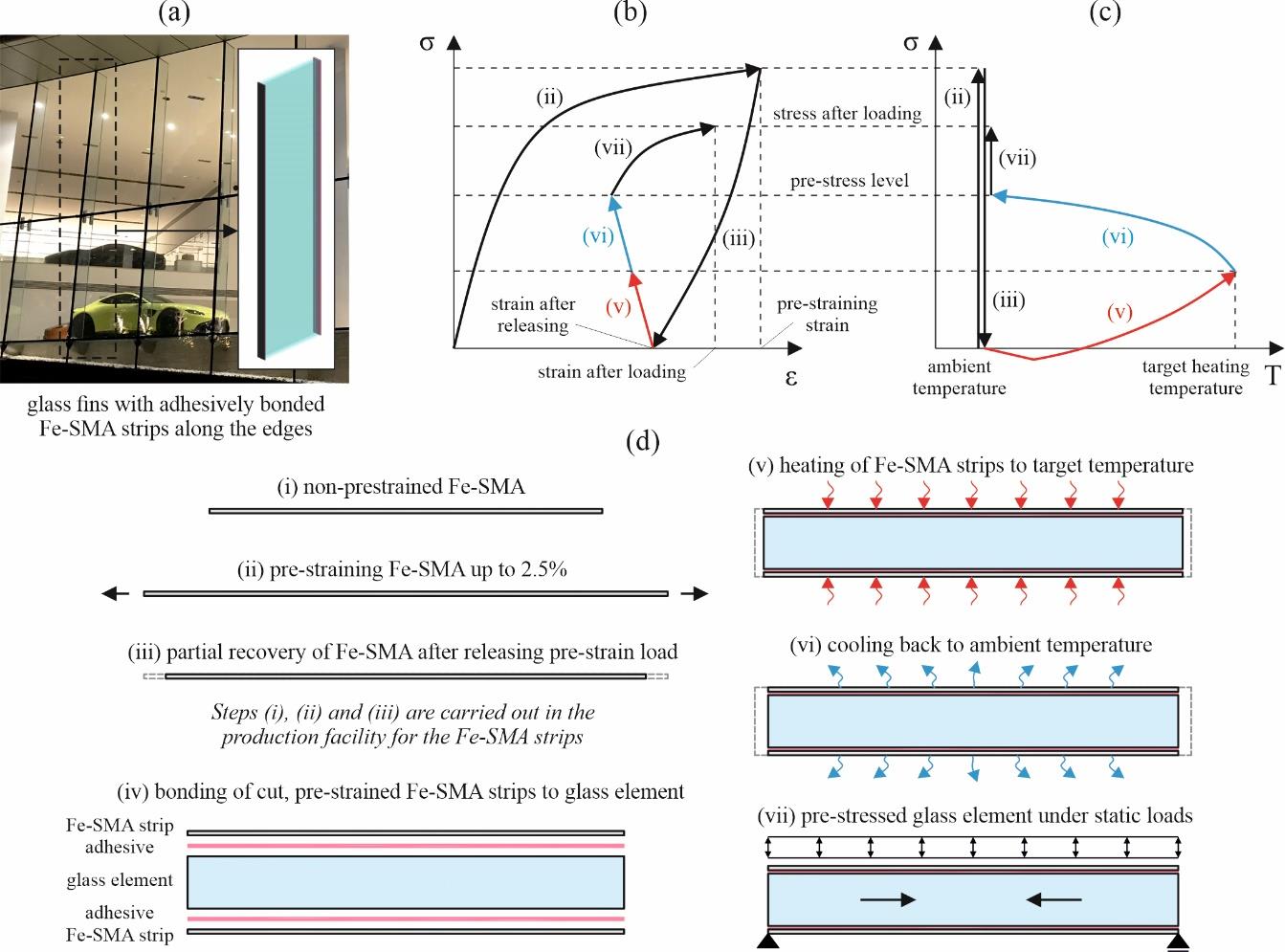

Previous research has evidenced that by adding a ductile reinforcement on the tension side of a glass beam, for instance by adhesive bonding, its post-cracking behaviour and redundancy were improved, while an additional pre-stressing of this reinforcement further helped to increase the initial cracking resistance. Past investigations used steel tendons or stainless steel strips, which required rather complex setups and procedures for mechanical pre-stressing. This study aims to introduce an easier-to-apply procedure with strips made of an iron-based shape memory alloy (Fe-SMA), which has the property of remembering its initial shape after a phase transformation from austenite to martensite. The Fe-SMA strips can be anchored to a parent structure as pre-strained strips, in case of a glass substrate by adhesive bonding. After activation of the Fe-SMA through a heating and cooling process, a tensile stress is generated in the strip, which applies a compressive stress field into the parent structure. This work discusses the results from first feasibility investigations dealing with the choice of adhesive and identifying a suitable activation procedure for Fe-SMA strips adhesively bonded to glass elements. The effective bond length, which needs to be considered when defining the anchorage length, was determined for two structural adhesives. While for the high-strength, brittle 2c-epoxy adhesive SikaPower®-1277, shorter bond lengths of a little more than 120 mm were sufficient, for the more ductile 2c-methacrylate adhesive Araldite® 2047-1, longer bond lengths were necessary for the same load level (more than 240 mm). Furthermore, an activation procedure by electrical resistive heating was applied, which (i) allowed sufficient heating of the Fe-SMA for activation, (ii) avoided too high instant temperature changes in the glass and (iii) did not affect the required anchorage bond length.

Published

Issue

Section

Hybrid & Composite Glass Components

License

Copyright (c) 2022 Vlad-Alexandru Silvestru, Zhikang Deng, Julien Michels, Lingzhen Li, Elyas Ghafoori, Andreas Taras

This work is licensed under a Creative Commons Attribution 4.0 International License.