Recycled glass mixtures as cast glass components for structural applications, towards sustainability

DOI:

https://doi.org/10.7480/cgc.7.4482Downloads

Abstract

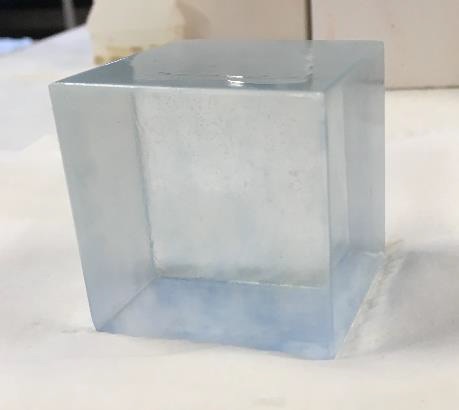

The problem of sustainability represents one of the most important issues that the world has to face nowadays, not only in terms of energy consumption and of the consequent CO2 emissions, but also in terms of material waste streams that end in landfill. 38 million tons of glass waste are produced every year in the European Union and new targets have been set for 2020 towards a more sustainable management of such wastes. Nowadays, only the container glass industry has reached a considerable recycling rate, while for all the other sectors we are still witnessing downgrading processes. Looking at the world of construction, glass has been more and more employed as a structural material thanks to its high transparency and compression strength. Although the use of glass can be attractive under multiple aspects and its production is continuously increasing, once employed as a construction element, it is rarely reused or recycled due to the high-quality requirement demanded to the industry of production. Nevertheless, besides its main applications as a 2-dimensional element, the new technology of cast glass has been recognised as a potential mean of glass recycling. Here, glass is designed and used under the form of repetitive 3-dimensional units assembled in a whole geometrical shape. In fact, thanks to its higher load-bearing capacity under monolithic shapes, this glass can admit less restrictions and potentially incorporate different types of waste. For this reason, the aim of this experimental work is to find a possible combination between glass families, specifically soda-lime, borosilicate and lead-crystal glass, to be recycled as cast glass components. Each type of glass was powdered or grinded under the form of cullet and different mixtures were prepared to be melted at temperatures of 970°C, 1120°C and 1200°C through the kiln-cast tecnique. Finally, an experimental splitting test was performed to define a force trend and a fracture behaviour for each sample. Some preliminary results have been achieved drawing the guidelines for a further investigation. Soda-lime-silica glass and lead-crystal glass mixture revealed to be the most compliant glass recipe with the required physical and mechanical properties, when reheated at 1120°C. The decrease in the melting temperature of the compound and the higher transparency given by the addition of lead glass revealed the potential benefit, in terms of sustainability, for future projects.

Published

Issue

Section

Glass in Facades

License

Copyright (c) 2020 Giulia Maria Anagni, Telesilla Bristogianni, Enrico Sergio Mazzucchelli

This work is licensed under a Creative Commons Attribution 4.0 International License.