Experimental and numerical investigation into the mechanical behavior of embedded laminated connections

DOI:

https://doi.org/10.7480/cgc.7.4551Downloads

Abstract

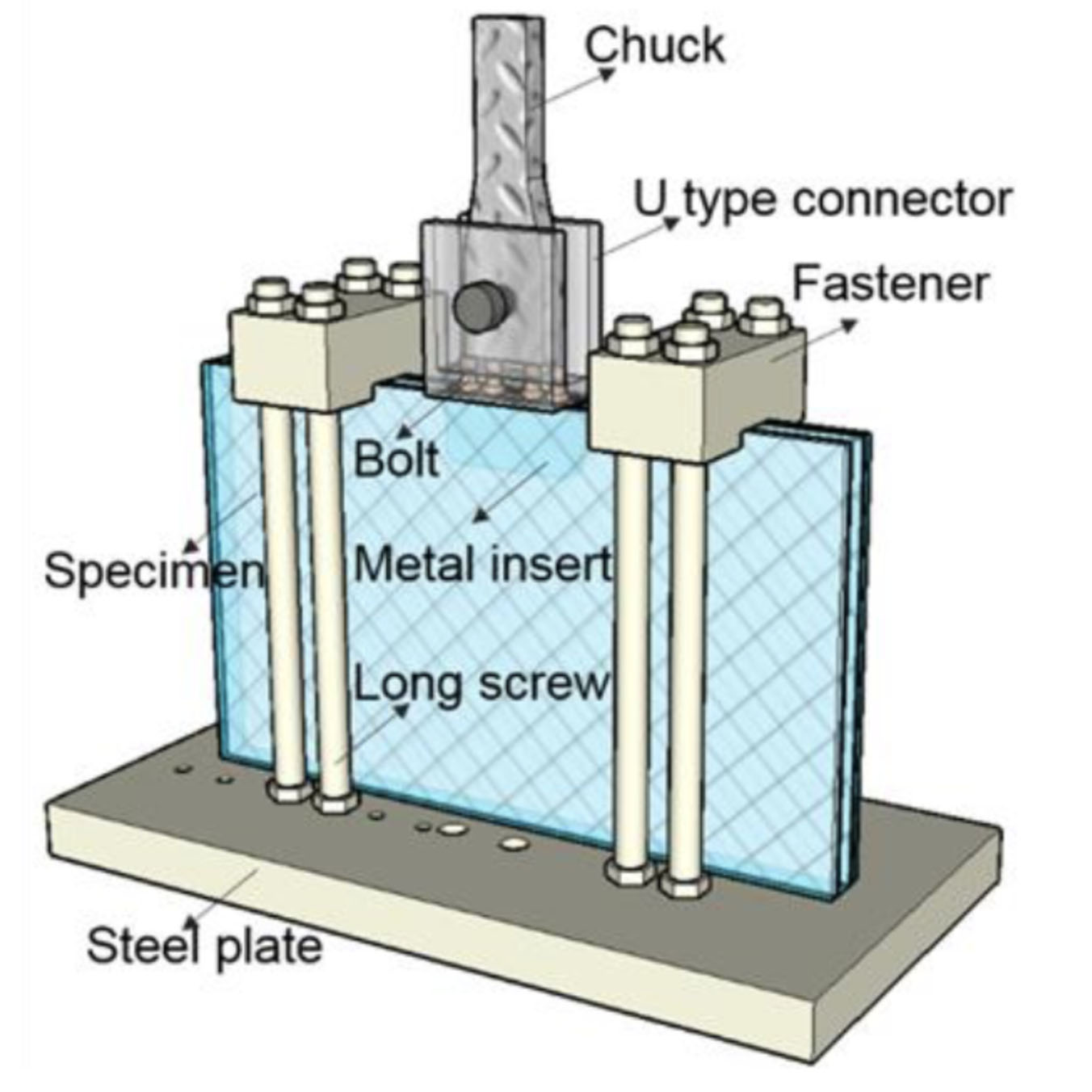

Embedded laminated connection (ELC) is a novel type of connection in structural glass and its application increases the transparency and surface flatness of structural glass elements. In this study, laboratory tests have been conducted to investigate the mechanical behavior of embedded laminated connections. Two groups of ELC, i.e. ELC laminated with triple annealed glass layers (TA-ELC), ELC laminated with double outmost tempered glass layers and one mid annealed glass layer (DT-ELC). The data of the pull-out force and displacement of the ELC under the pull-out load was collected and analyzed. The experimental results reveal that the TA-ELC group exhibits brittle failure, whereas DT-ELC group significantly improves the maximum loading capacity. Compared to TA-ELC group, the outmost tempered glass layers in DT-ELC group can render greater ductility. The study also indicates that the crack initiation as well as the final failure of the TA-ELC are both induced in the outmost glass layers. The crack initiation of the DT-ELC is firstly observed in the mid glass layer and the final cracking at failure is generated in the outmost glass layers. A numerical study was also performed to simulate the entire failure process. It is then found that materials in TA-ELC group keeps behaving in an elastic manner before the crack initiation. In DT-ELC, the stable stage of the pull-out force is caused by the yielding of SG layers.

Published

Issue

Section

Joints, Fixings & Adhesives

Keywords:

Structural Glass, Embedded Laminated connection, Pull-out load, Laboratory testLicense

Copyright (c) 2020 Chenjun Zhao, Jian Yang, Xing-er Wang, Iftikhar Azim

This work is licensed under a Creative Commons Attribution 4.0 International License.