Experimental Investigation into SLS Glass Surface Modification Using KrF Excimer Laser

DOI:

https://doi.org/10.7480/cgc.7.4485Downloads

Abstract

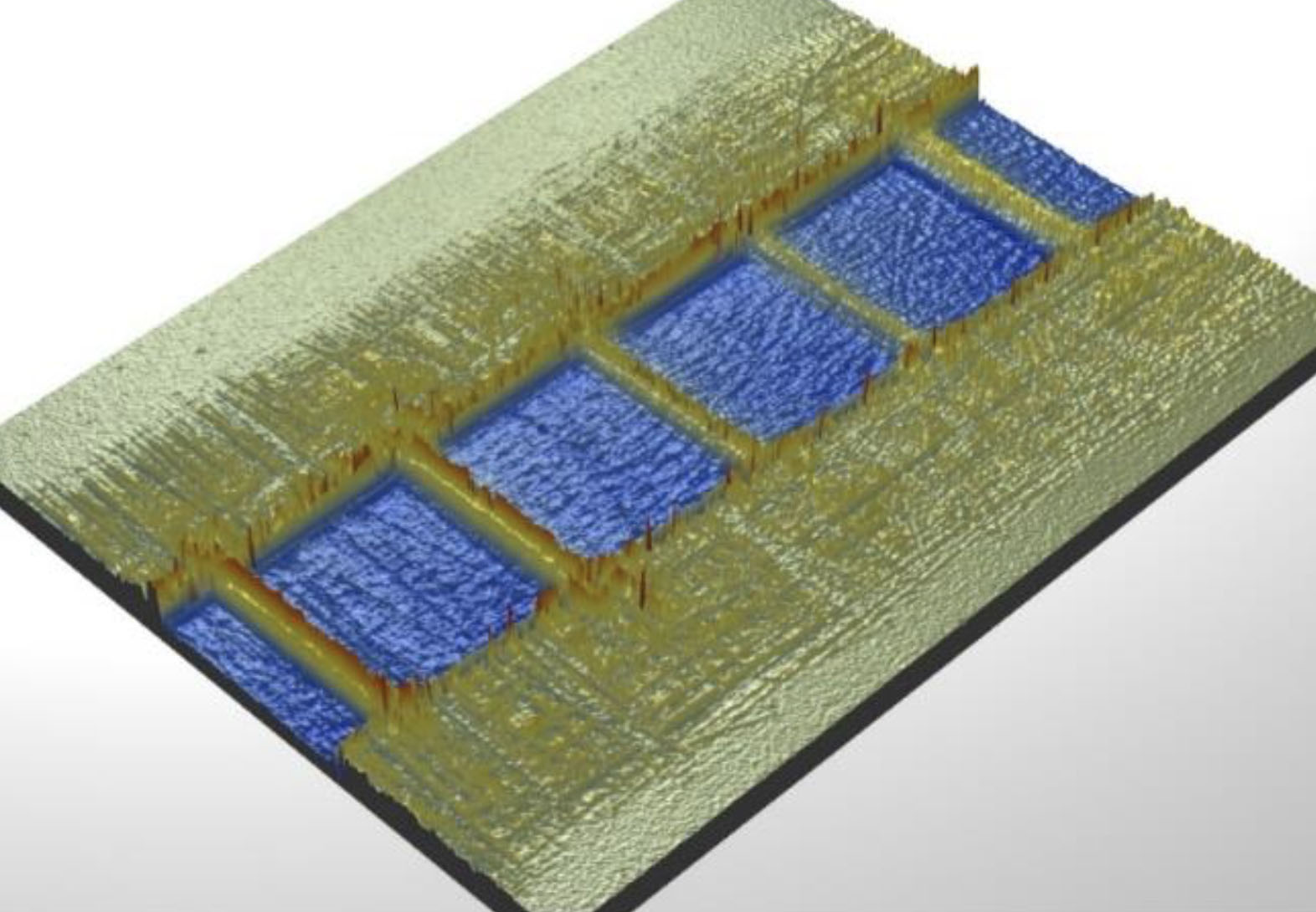

Glass is a brittle material and any damage or modification of its surface may have a profound impact on the strength. To modify the glass surface, the precision of the instrument is determining for achieving the most reliable results. Nowadays, laser technology as a non-contact tool is employed as a glass cutting, drilling and holing tool in many applications such as sensors and optical communications. Along with high speed, flexibility, and scalability, lasers with short pulse duration can break the interatomic bonds before perturbing the lattice. Among lasers, excimer micromachining lasers have some advantages in terms of surface morphology, including depth control, edge quality, and minimizing peripheral thermal damage as the ablation process is more likely to be material-removing instead of heating. This article aims to examine the interaction of krypton fluoride (KrF) excimer laser with the soda-lime silica (SLS) glass by fabricating grooves and microholes.

Published

Issue

Section

Strength & Stability

License

Copyright (c) 2020 Shahryar Nategh, Pieter Vijverman, Jeroen Missinne, Jan Belis

This work is licensed under a Creative Commons Attribution 4.0 International License.