GS&E journal > Investigating the flexural strength of recycled cast glass

Downloads

Abstract

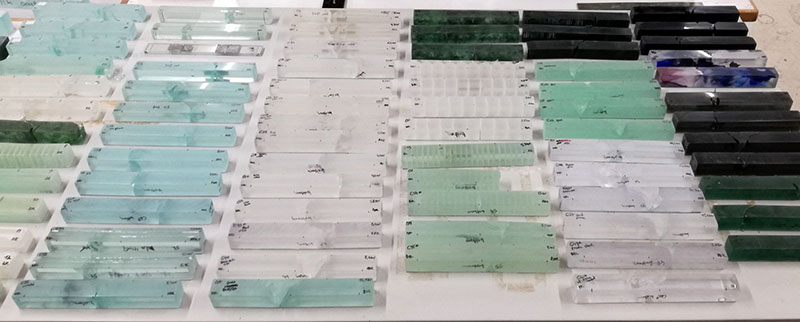

Currently, tons of high quality commercial glass are down-cycled or landfilled due to contaminants that prevent close-loop recycling. Yet, this glass is potentially a valuable resource for casting robust and aesthetically unique building components. Exploring the potential of this idea, different types of non-recyclable silicate glasses are kiln-cast into 30*30*240mm beams, at relatively low temperatures (820 oC - 1120 oC). The defects occurring in the glass specimens due to cullet contamination and the high viscosity of the glass melt, are documented and correlated to the casting parameters. Then, the kiln-cast specimens and industrially manufactured reference beams are tested in four-point bending, obtaining a flexural strength range of 9-72MPa. The results are analysed according to the role of the chemical composition, level of contamination and followed casting parameters, in determining the flexural strength, the Young’s modulus and the prevailing strength-limiting flaw. Chemical compositions of favourable performance are highlighted, so as critical flaws responsible for a dramatic decrease in strength, up to 75%. The defects situated in the glass bulk, however, are tolerated by the glass network and have minor impact on flexural strength and Young’s modulus. The prerequisites for good quality recycled cast glass building components are identified and an outline for future research is provided.

Published

Issue

Section

Strength & Stability

Keywords:

cast glass, glass flexural strength, glass defects, recycling of glass waste, mechanical properties of glassLicense

Copyright (c) 2020 Telesilla Bristogianni, Faidra Oikonomopoulou, Rong Yu, Fred A. Veer, Rob Nijsse

This work is licensed under a Creative Commons Attribution 4.0 International License.